FAQ

Your Questions, Answered.

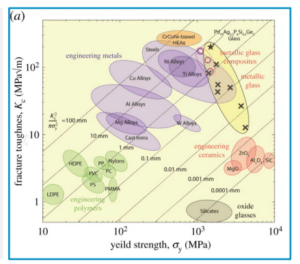

An amorphous metal is a solid metallic material, usually an alloy, with disordered atomic-scale structure. Most metals are crystalline in their solid state, which means they have a highly ordered arrangement of atoms. Amorphous metals are non-crystalline, and have a glass-like structure.

- Hardbanding is a process of applying a layer of hard metal to a softer metal part, typically to protect the softer metal from wear and tear. This is often done in the oil and gas industry, where hardbanding is used to protect drill pipes and other components from the

abrasive effects of drilling through rock and earth. - Hardbanding is a complex process that requires specialized knowledge and equipment. It is important to have a qualified hardbanding contractor perform the work to ensure that the hardband is applied properly and meets the specific needs of the application.

- Hardbanding can be applied using a variety of methods, including welding, plasma transfer arc (PTA) cladding, and laser cladding. The choice of method will depend on the specific application and the desired properties of the hardband.

- Hardbanding materials are typically made of high-alloy steels, tungsten carbides, or chromium carbides. These materials are very hard and wear-resistant, making them ideal for protecting softer metals from abrasion.

Benefits of Hardbanding:

- Increased wear resistance

- Extended service life of components

- Reduced maintenance costs

- Improved safety

- Increased productivity.

Hardbanding can be used to protect a variety of metal parts, including:

- Drill pipes

- Casing

- Drill collars

- Mud motors

- Mud pumps

- Valves

- Impellers

- Shafts

- Gears

Hardbanding is an effective way to extend the life of metal parts and reduce maintenance costs. It is a widely used process in the oil and gas industry, but it is also used in other industries, such as mining, construction, and manufacturing.

Our unique blend of advanced materials and innovative application techniques offers unparalleled resistance to wear, extending the life of drilling components significantly.

Absolutely. We work closely with our clients, from academic research teams to industrial R&D departments, to tailor our solutions to their unique challenges and requirements.