Introduction to the development history and trend of amorphous alloy materials

By Wang Weihua

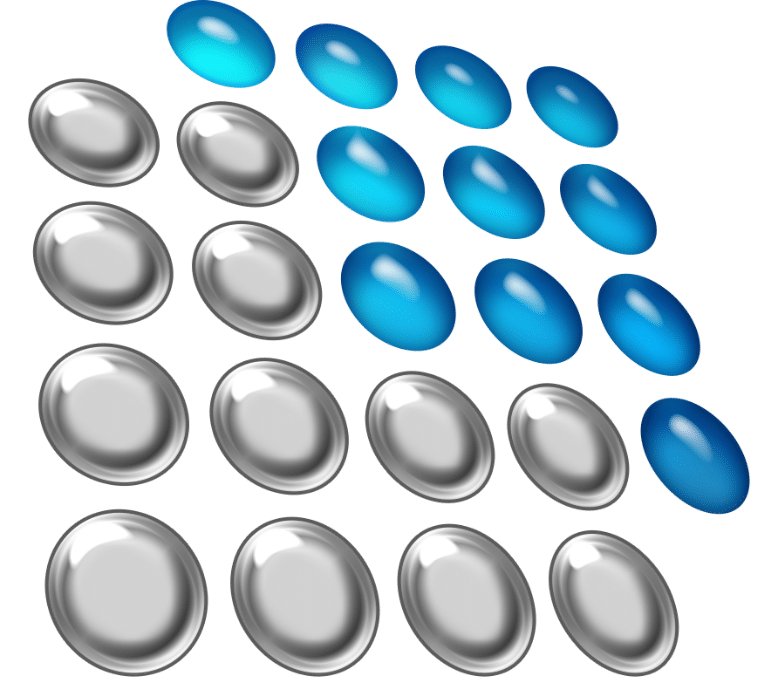

Metal materials are closely related to the development history of human civilization for 10,000 years, and the development and use of metal materials often become milestones in the division of different human civilization eras, such as the Bronze Age, the Iron Age, the Iron Age, etc. Every development of metal materials will greatly promote the great progress of human civilization and productivity. Amorphous alloy is a new type of metal material obtained in recent decades through the new technology of modern metallurgy – rapid solidification technology and entropy control concept – inhibiting the crystallization of alloy melt atoms, maintaining and regulating the disordered structure characteristics of the melt, also known as metallic glass, or liquid metal. This material is synthesized by modulating the new approach and concept of “order” or “entropy” of the material structure, and has the properties of glass, metal, solid, liquid and other substances, which subverts the traditional idea of design and preparation of metal materials based on composition and defects (Fig. 1), breaks through the inherent concept of the atomic structure of metal materials, and improves the strength, toughness, elasticity, corrosion resistance, radiation resistance and other performance indicators of metal materials to an unprecedented height, changing the appearance of ancient metal structural materials. Disordered alloys such as amorphous and high-entropy have shown great significance and strategic value in basic research and technological applications, and play an increasingly important role in high-tech fields such as energy, information, environmental protection and energy conservation, aerospace, medical and health care, and national defense. Fundamental research in the field of disordered alloys will continue to drive the materials revolution and a deeper understanding of material behavior, and can lead to the creation of new material devices and systems.

1) R&D trend and progress of amorphous alloy materials

1.1) R&D trend of amorphous alloys

The research and development of amorphous alloy materials has reached four peaks, and nearly 100 amorphous alloy systems such as iron, copper, zirconium and rare earth based have been developed. The first peak was around 1960, when Professor Duvitz of the California Institute of Technology invented the rapid solidification metallurgical technology and prepared amorphous alloys for the first time. The second peak period was around the 80s of the 20th century, led by Japan and the United States, and the industrial technology of amorphous alloy strips, the preparation technology of amorphous alloy powder and thin film, and the application of amorphous alloy soft magnetism were developed. The third peak period was in the 90s of the 20th century, mainly led by Japan and the United States, during this period, through the composition control, the viscosity coefficient of the metal melt was greatly improved, and the critical size of the amorphous alloy was increased from the micron level to the centimeter level, and the amorphous alloy material entered the era of bulk alloys, which greatly expanded its application range and field. The fourth peak period is after 2000, led by the United States and China, China’s amorphous alloy patents account for about 76% in recent years, and the main technologies and progress involve the preparation and application of large amorphous alloys such as iron-based, copper-based, and zirconium-based, the large-scale application of strips in distribution transformers and soft magnetic cores, the invention of high-entropy alloy materials and high-entropy amorphous materials, and the introduction of concepts such as disordered alloys in the research and development of entropy control. Disordered alloys mainly include amorphous alloys and high-entropy alloys. The main characteristics of amorphous alloys are disordered composition and long-range disordered structure, while the main characteristics of high-entropy alloys are ordered structure but disordered composition. The future development trend of disordered alloys is to develop a new generation of high-performance, low-cost, and functional materials that break through the existing size limitations, and expand their applications in high-frequency motors, aerospace and automobiles, information technology and other fields. The 2021 Nobel Prize in Physics was awarded to the Italian scientist G. Giorgio Parisi. Parisi) in recognition of his pioneering contributions to the understanding of complex disordered physical systems, and the scientific significance of the study of disordered systems themselves. As relatively simple disordered systems, disordered alloys such as amorphous and high-entropy provide a model system for the study of basic problems in physics and materials science, which will greatly promote the development of complex disordered systems.

1.2) The research and development of disordered alloys in China has jumped to the international first-class level

China’s research and development of amorphous alloys started in the 70s of the 20th century, when the United States, Japan, the Soviet Union, Germany, the United Kingdom and other European countries were the most active countries in this field. At present, most of the outstanding scientists in Japan and Europe have retired, and there are far fewer high-level successors than before, and the technology and level have gradually fallen behind. At present, the United States mainly focuses on the basic physics, simulation and mechanism research of amorphous alloys, while the application exploration is mainly concentrated in high-tech fields such as aerospace. At present, China’s amorphous alloy researchers account for 2/3 of the world, and the level of young researchers is getting higher and higher, and the level of research and development has surpassed that of Japan and the European Union, which is comparable to the United States, and has become the world’s first echelon. For example, so far, 36 alloys with metal elements as the matrix have been found to prepare bulk amorphous alloy components, of which 28 have been found in China.

Especially in the past 10 years, the most important progress of disordered alloys is the development of high-entropy alloys. High-entropy alloy is a disordered alloy material with complex chemical composition, no major elements, orderly structure and disordered composition developed based on the design idea of entropy regulation, which greatly expands the space for material development. High-entropy alloys have shown many strange and extraordinary properties, and their research and application have become a research hotspot in the field of metal materials. Many high-entropy alloys developed abroad have obvious application orientation for military equipment needs. Researchers in Taiwan first developed high-entropy alloys on the basis of amorphous alloys, leading the development of disordered alloys. The R&D of disordered alloys in China can leap to the world’s first-class is closely related to the increasing investment in science and technology in China, the long-term accumulation of basic research, the industrial demand for new metal materials in large manufacturing countries, and the emergence of young talents (domestic training and overseas return). The long-term accumulation of basic research in the field of amorphous alloys has provided support and impetus for the industrial application of such new materials. At the same time, relevant basic research also draws from industrial applications as a source of problems and progress.

1.3) Constraints of basic science issues on the research and development of amorphous alloy materials

The basic scientific problem is the biggest bottleneck restricting the development of disordered alloy materials. Due to the complexity of disordered structure, the existing theories, models and research paradigms of solid state physics and materials science cannot effectively explain and describe its structure, the relationship between structure and performance, and new phenomena, and new scientific theories, new methods and new paradigms are urgently needed. At present, the field of amorphous alloy materials is facing four basic scientific problems: (1) glass transition mechanism, that is, how the alloy liquid is condensed into an amorphous state with long-range disordered structure and substable energy; (2) deformation mechanism, that is, how the structural disordered alloy system dissipates the deformation of external forces, and the calibration of the structural unit that dissipates energy; (3) the amorphous structure has not been effectively described by a unified model; (4) the relationship between structure and properties, formation and deformation has not been established, which hinders the efficient research and development of amorphous materials. Performance design and regulation. Breakthroughs in basic research can greatly promote the efficient research and development and performance optimization of new high-performance disordered alloy materials.

2) Prospects and challenges of the amorphous alloy industry

2.1) Main application scenarios of amorphous alloys

As a new metal material with integrated structure and function, the industrialization prospect of amorphous alloy is very broad. The United States, Japan, Germany and other countries have invested heavily in expanding their application scenarios and promoting the development of related industries. The R&D level, market competitiveness and industrial scale of companies in the field of amorphous alloys such as Liquid Metal Technology and Glass Metal Technology of the United States, Hitachi Metals of Japan, VAC of Germany, and Yi’an Technology and Taiyi Technology in China are at the world’s leading level. At present, there are 4 main application areas of amorphous alloys.

(1) High-performance structural materials. Because the amorphous alloy has the characteristics of high strength (cobalt-based more than 5GPa, lightweight titanium-based more than 2GPa), high toughness (palladium-based more than 200MPa/m1/2), high elastic deformation (2%), self-sharpening characteristics, radiation resistance, corrosion resistance, etc., it has been used as a warhead and armor material for a new generation of armor-piercing and armor-piercing shells. Space equipment usually faces extreme environments such as high temperature difference, strong irradiation, strong corrosion, and high strain, which requires extremely high material performance. The good comprehensive properties of amorphous alloys can make them show high stability in complex environments such as cold and hot cycling in space environment and high-energy particle irradiation in space environment, and its atomic-level surface flatness, low thermal expansion coefficient and precision forming performance are expected to be used as mirror materials for space mirrors to focus sunlight to realize the utilization of space in-situ resources such as lunar soil refining and oxygen production. In addition, amorphous alloy can meet the demanding performance requirements of the large-scale deployment mechanism of spacecraft, and is the key material for the elastic deployment mechanism of spacecraft.

(2) Soft magnetic materials. Amorphous alloy soft magnets and nano-soft magnets and composites developed from amorphous alloys play an important role in soft magnetic materials (Fig. 2). Due to its high magnetic saturation strength, high permeability, low coercivity, low saturation magnetostriction, and easy completion of magnetization and demagnetization processes, many soft magnetic properties of amorphous alloys are far superior to traditional silicon steel sheet materials and crystalline magnetic materials. Iron, nickel and cobalt-based amorphous alloy soft magnetic strips, wires and powders have been widely used in various transformers, inductors and sensors, magnetic shielding materials, radio frequency identifiers, etc., and are indispensable and important basic materials in the fields of power, electronics and electronic information. The iron loss of the distribution transformer with amorphous alloy as the core is only 1/5-1/10 of the silicon steel sheet. It is estimated that about 30%-60% of China’s power grid losses come from transformers, even if only 15% of the existing transformers are replaced, their power savings can reach 9 billion kWh/year and CO2 emission reduction of 8 million tons/year. China has become the second country in the world after Japan to have the mass production capacity of amorphous alloy transformer raw materials, and has formed a 100-billion-level amorphous core high-end manufacturing industrial cluster, with a market of nearly 100 billion yuan. Amorphous alloy soft magnetic materials will soon be widely used in the rapidly developing field of electronic information. A wide range of electronic devices in these fields are widely used in light, thin, small and highly integrated switching power supplies, and the means used are high-frequency electronic technology, which requires the soft magnet cores of transformers and inductors to be suitable for high-frequency applications. Bulk amorphous alloys with high saturation magnetic inductance, high permeability, low loss, and easy processing can be directly cast or processed into miniature cores with various complex structures, and then made into transformers or inductors, which are used in various electronic or communication equipment. However, the defects in the preparation process of amorphous strip lead to its poor resistance to sudden short circuits, and the noise and brittleness caused by amorphous magnetostriction are still world-class problems. Motor is an extremely important power equipment for industrial production and social life, and its power consumption ranks first in all kinds of electrical equipment, and the global motor electricity consumption accounts for more than 50% of the world’s total electricity consumption, accounting for about 70% of industrial electricity. At high frequencies, the amorphous alloy motor core can significantly reduce the motor loss and increase the efficiency by 3%-20%. Amorphous alloy motors have high power density, light weight, small size, and low heat generation, thus solving the problem of excessive volume caused by the need to equip heat dissipation devices in traditional high-frequency devices, and are expected to play an important role in electric drives, high-speed spindles, aviation generators and military fields. At present, the development of related industries has not yet been formed in the world, and domestic scientific research units such as Songshan Lake Materials Laboratory and Institute of Physics of the Chinese Academy of Sciences are conducting research and development of a new generation of amorphous soft magnetic materials in the laboratory stage with the support of major projects of the National Natural Science Foundation of China, and will cooperate with Antai and other enterprises to carry out the development of related application technologies.

(3) Catalytic materials. Compared with the single active site of crystalline materials, amorphous alloys have unique intrinsic catalytic activity, strong activation ability and dense active centers. Amorphous alloy catalysts can change the composition in a wide range and adjust the electronic structure with the composition to obtain a more ideal catalytic active center, so as to improve the problem of internal diffusion of reactants in traditional heterogeneous catalysts and affect the surface reaction, which has been widely used in the petroleum industry, environmental protection and other fields.

(4) Basic materials for manufacturing. Amorphous alloys are the basic materials of the manufacturing industry. For example, the elasticity of flexible gears based on amorphous alloys is dozens of times higher than that of conventional metals, and has many advantages such as simple structure, large transmission ratio, small size, long life, etc., and can work normally even in harsh environmental conditions such as space, and does not need to add lubricating oil after entering the sand particles, which can be used in rockets, satellites, aircraft, tanks and radars in the follow-up system and vacuum sealed transmission, robot arm connection, and precision testing fields. For example, BYD has improved the preparation process of iron-based, copper-based and zirconium-based amorphous alloys to manufacture battery thin-film electrodes.

2.2) Challenges and opportunities for the industrialization of amorphous alloy materials

In the process of industrial transformation of many scientific research achievements, various factors will cause their failure, that is, there is a “valley of death” in the transformation process (Figure 3). In the field of amorphous alloys, China’s related patent applications rank first in the world, but there is still a lack of leading enterprises with international standards. Although China has a huge amorphous alloy application market, most of the materials currently used are based on the early development systems abroad, and many new amorphous alloy systems developed in China have not been applied on a large scale. The R&D capabilities of amorphous alloys in domestic laboratories and the correlation between enterprises and markets are not strong. In the past ten years, the bottleneck of large-scale industrial application of bulk amorphous alloys in China has not been broken.

The successful market transformation of amorphous alloy scientific research achievements requires the organic combination of talents, technology, capital and management. With more than ten years of basic and applied research accumulation of amorphous alloys in China, there is a vigorous and sound manufacturing industry and a low industrialization threshold, and the application research of a new generation of bulk amorphous alloys is very likely to make breakthroughs in China. For example, the Songshan Lake Materials Laboratory in Guangdong has gathered sufficient resources for various innovation transformations, including talents, capital, industrial clusters, as well as new mechanisms and flexible policies supported by the government, to form a healthy and favorable environment for the industrialization of scientific and technological achievements, and is looking forward to working with related enterprises to jointly develop amorphous alloy materials such as high-frequency soft magnetics, flexible gears, and high-performance 3C devices for the third generation of semiconductor electronic components.

At present, the soft magnetic materials used for device power supply and inductance have low saturation magnetic inductance and high high-frequency loss, which seriously restricts the improvement of power density and operating frequency of third-generation semiconductor electronic components such as gallium nitride and silicon carbide, making it difficult to give full play to their advantages. The development of soft magnetic materials that match the power density and operating frequency of third-generation semiconductor devices is expected to promote the application of third-generation semiconductors in high-power and high-frequency devices, and then promote the development of key fields such as 5G communication base stations, satellite communications, radar aviation, and smart cars. At the same time, relevant domestic research institutes and universities are also cooperating with domestic enterprises such as Yi’an, Taiyi, Qingdao Yunlu, etc., and strive to promote amorphous alloys and high-entropy alloys to green energy saving, environmental protection, as well as ultra-sensitive detector and sensor materials, aerospace materials, robots and other application fields.

3) Enlightenment and suggestions for the development of disordered alloy materials

The new material industry is a strategic, basic industry, and a key area of high-tech competition, and the development of new structural materials or functional materials will have an important impact on the development of science and technology and society. In the field of metal materials, amorphous, high-entropy and other disordered alloys as new metal materials, have a wide range of application scenarios, and China has the advantages of international advanced scientific and technological research and development; through the introduction of new ideas, creative processes and technologies in the field of metal materials, the development of rich industrial application scenarios, can make metal materials research and industry in China have a leap forward, and promote the upgrading of metal materials industry. In order to comply with the law of transformation and development of scientific and technological achievements in the new historical period, accelerate the establishment of a new model for the research and development of disordered alloy materials, and optimize the research and development system of disordered alloys, five suggestions are put forward.

(1) Pay attention to the key basic scientific and technical problems of disordered alloys such as amorphous and high-entropy. There are still a large number of key scientific and technical problems in the research and application of disordered alloys such as amorphous alloys. It is suggested to build a cooperative innovation platform for research institutions and enterprises and a disordered alloy research center, focusing on solving the major basic scientific problems and technical bottlenecks restricting the large-scale application of disordered alloys, including: exploring the formation laws and influencing factors of disordered alloys, introducing new material research and development concepts, developing new preparation methods and characterization technologies, combining with material databases to realize the design and development of new disordered alloy materials on demand, and developing large-scale preparation and processing equipment and technology for disordered alloys of bulk materials.

(2) Promote the cross-integration of disordered alloys such as amorphous and multi-disciplines. Today, the boundaries between scientific research and technology applications, scientific institutions, scientific exploration and industrial R&D are fluid and increasingly blurred. How to deal with the above interaction has become an important mechanism for the development and application of amorphous alloys. At present, the industrialization level of amorphous alloys in China lags behind the development of science and technology, and the innovation ability and scale of enterprises are insufficient. Suggestions: (1) Organize and focus on the key application technologies and scientific issues that affect the development prospects of disordered alloys at the national level, provide continuous funding for them in a planned and deployed manner, and jointly tackle key problems with scientific research institutes, universities and enterprises;The whole chain research and application mode of “design-R&D-application” excavates more application scenarios and realizes their application in more fields. For example, for the more mature amorphous alloy soft magnetic, develop a new generation of high-performance materials, realize the automation and intelligence of the preparation process, increase market share and actively explore the international market. (2) Promote the leapfrog development of amorphous alloy materials in major cross-cutting fields. For example, in the field of soft matter, the cross-study of amorphous alloys and soft matter can condense common frontier problems and establish a universal theoretical framework; in the field of information, amorphous alloys should be promoted to meet the integration requirements of information materials in the post-Moore era for multifunctional properties; in the field of new energy, the unique structural characteristics, mechanical and electrochemical properties of amorphous alloys can be used to make them potential new hydrogen storage materials and energy-saving materials; in the field of biomedicine, amorphous alloys have high strength, The low elastic modulus and good biocompatibility make it a good application prospect as a biological implant.

(3) Introduce new concepts such as material genetic engineering, artificial intelligence, and big data, and give full play to the role of scientific large-scale devices. Since the 21st century, the rapid development of big data, artificial intelligence, and information technology has profoundly changed the pattern and paradigm of material research and development, and greatly promoted the progress of material research and development and application. Preliminary studies show that new concepts and methods such as materials genetic engineering, artificial intelligence, and big data, as well as large scientific devices such as neutron scattering and attosecond lasers, will have a subversive impact on the research and development of amorphous alloy materials, and can greatly improve the efficiency and cost of research and development and application.

(4) Improve the underlying basic technology of the industry, and comprehensively promote the upgrading of the disordered alloy material industry. The research of new disordered alloys, such as the third-generation bulk amorphous alloys and high-entropy alloys, has made great progress, but at present, China’s amorphous alloy industry is still mainly the first-generation amorphous strips and powders, which are in urgent need of industrial upgrading. Through cooperation, scientific research institutions and scientists should help enterprises cultivate talents, improve their technical level, and seek new application scenarios and markets. By driving the upgrading of the amorphous alloy industry, it will in turn promote the development of basic research on disordered alloys. Through the mechanism design, give full play to the leverage role of financial funds, increase the state’s investment in basic research, drive and improve the level of scientific and technological investment of local and enterprises, and give full play to the decisive role of the market in the allocation of innovation resources; at the same time, encourage the participation of social and enterprise funds, and form a diversified amorphous alloy research and development resource investment mechanism.

(5) Pay attention to academic exchanges and international cooperation in the new situation and new era. The R&D and application of amorphous alloys should pay attention to and make full use of the convenience of the information age, promote the popularization of amorphous alloy science, and publicize the significant impact of disordered alloy materials on society.

Contact Us

For inquiries or to discuss your specific needs, please contact us.